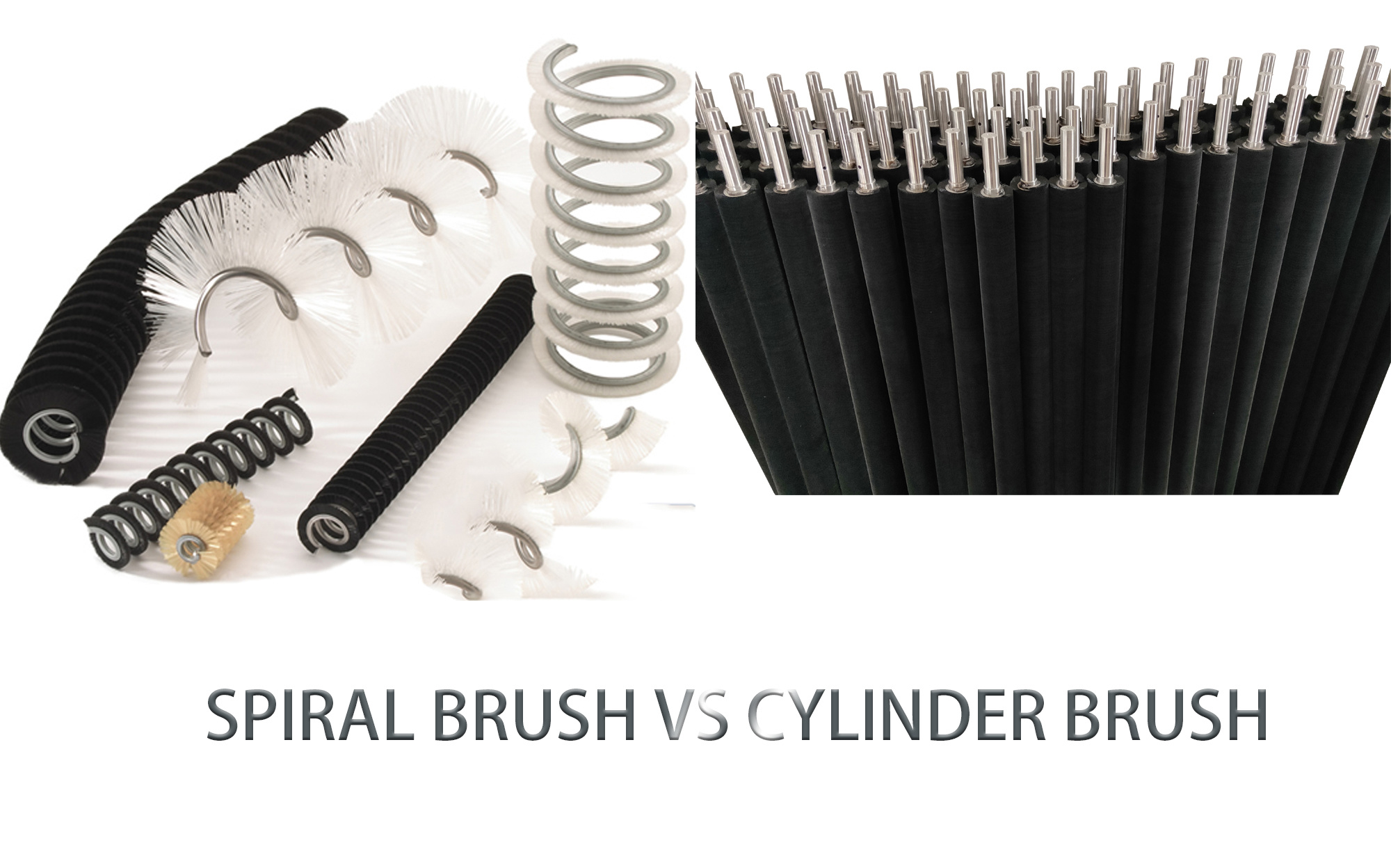

Choosing Your Roller Brush: Spiral vs. Spiral Wound Cylinder—A Quick Comparison

2025-10-20

Choosing the Right Roller Brush: Spiral Brush vs. Spiral Wound Cylinder Brush

Industrial roller brushes are essential for countless applications, but choosing the correct type is crucial for optimal performance and efficiency. Below is a breakdown of the two primary cylinder brush styles to help you determine the best fit for your needs.

(As seen in the first photo) This type features bristles punched directly into a solid core in a dense, continuous spiral pattern. It is known for its robust construction and high filament density.

Advantages and Disadvantages

| Advantages | Disadvantages |

|---|---|

| Extreme Density and Uniformity: The stable tufting method provides very high filament density and uniform pressure. | High Replacement Cost: The entire core must often be replaced when the bristles wear out, increasing maintenance costs. |

| Robust Construction: The solid core provides maximum stability for heavy-duty applications, high speeds, and aggressive scrubbing. | Less Flexibility in Pitch: The spacing of the spiral pattern (pitch) is fixed by the drilled holes and cannot be easily adjusted for different applications. |

| Superior Balance: The solid, fixed construction often results in better balance, ideal for high-RPM machinery. | Limited Debris Clearance: The lack of significant gaps between the bristle lines can lead to material buildup or clogging in very dusty or moist environments. |

Best Suited For: Heavy scrubbing, aggressive surface finishing, high-speed applications, and where maximum bristle density is required.

(As seen in the second photo) This brush is constructed by winding a continuous metal strip brush (containing the filaments) helically around a central shaft or core. The open structure is visible at the end.

Advantages and Disadvantages

| Advantages | Disadvantages |

|---|---|

| Cost-Effective Maintenance: Often, only the external coil needs to be replaced, allowing the core/shaft to be reused, reducing long-term costs. | Lower Maximum Density: The density is limited by the thickness of the metal channel. It is typically less dense than a staple-set brush wound with zero pitch. |

| Excellent Debris Clearance: The pitch (gap) between the coils allows dirt, debris, and liquids to fall through, minimizing clogging and maximizing efficiency. | Potential for Uneven Wear: If the pitch is too wide for the application, the cleaning action may be less uniform, potentially leading to slight striping or uneven wear. |

| Flexible Design & Diameter: Pitch and diameter are easily customized during the winding process, offering greater manufacturing flexibility for unique requirements. | Less Ideal for Aggressive Side-Loading: The reliance on the strip backing might make it less rigid than a solid-core brush under extreme side-to-side force. |

Best Suited For: Conveyor cleaning, material handling, surface treatments requiring debris clearance (e.g., fruit/vegetable washing), and long rollers where core reuse is desired.

Need further assistance? Our experts are ready to help you select the perfect brush for your specific industrial application!

Previous:

Contact us

TEL: 008613781822862

ADD: Building 1, No 115, Lane 1276, Nanle Road, Songjiang District, Shanghai 201611, China