In the world of industrial manufacturing and material handling, conveyors play a crucial role in ensuring smooth and efficient operations. However, the accumulation of dirt, debris, and unwanted materials on conveyor tracks can lead to costly downtime, maintenance issues, and even potential safety hazards. This is where conveyor strip brushes shine, providing an effective and reliable solution to keep your conveyors running seamlessly.

Overview:

Conveyor strip brushes are specially designed brushes that are mounted along the sides of conveyor tracks, creating a protective barrier against the ingress of contaminants. These brushes are engineered to deflect and sweep away any unwanted materials, ensuring that the conveyor track remains clear and free from obstructions. Whether you're dealing with overhead track conveyors or ground-floor systems, conveyor strip brushes offer a versatile solution tailored to your specific needs.

Applications:

Conveyor strip brushes find applications in a wide range of industries and settings, including:

Manufacturing facilities: Utilized in assembly lines, packaging operations, and material handling systems to maintain a clean and efficient production environment.

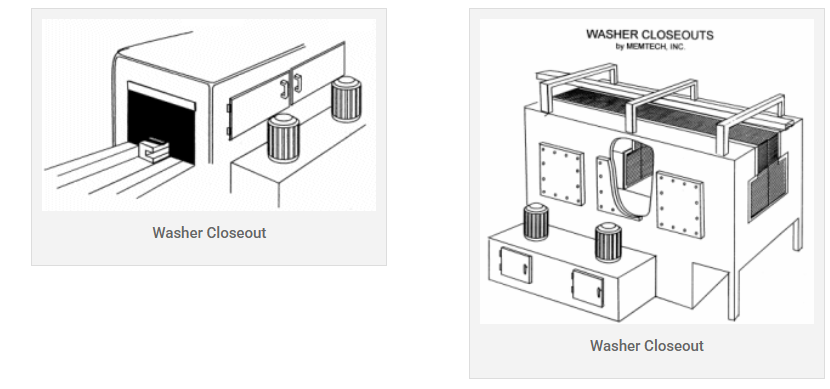

Food and beverage industries: Essential for maintaining strict hygiene standards and preventing contamination in food processing and packaging lines.

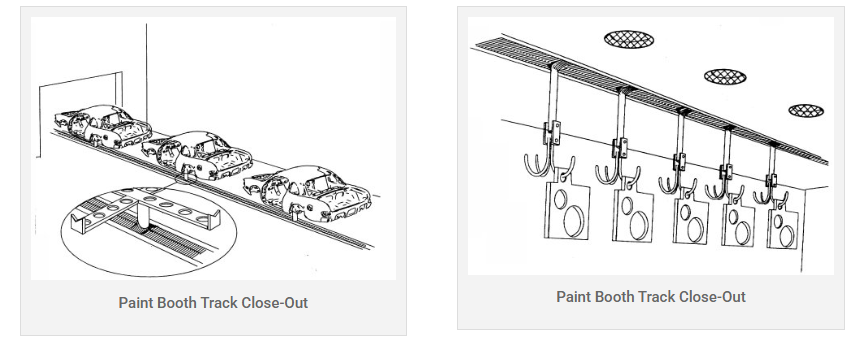

Automotive and aerospace industries: Applied in paint and finishing lines, ensuring a clean and controlled environment for superior product quality.

Warehousing and distribution centers: Implemented in high-traffic areas to prevent the accumulation of dust, debris, and other contaminants on conveyor systems.

Advantages:

Investing in high-quality conveyor strip brushes offers numerous advantages:

Increased productivity: By keeping conveyors free from obstructions, these brushes help minimize downtime and maximize operational efficiency.

Extended equipment lifespan: Protecting conveyor tracks from debris and contaminants reduces wear and tear, prolonging the lifespan of your conveyor systems.

Improved safety: A clean and well-maintained conveyor system minimizes the risk of accidents, ensuring a safer working environment for your personnel.

Cost savings: Preventive maintenance through the use of conveyor strip brushes can significantly reduce repair and replacement costs in the long run.

Features:

When selecting conveyor strip brushes, consider the following features:

Durable construction: Look for brushes made from high-quality materials, such as stainless steel or synthetic fibers, ensuring long-lasting performance and resistance to wear.

Customizable designs: Many manufacturers offer customizable brush configurations, allowing for tailored solutions to fit your specific conveyor system and application requirements.

Easy installation and replacement: Brushes should be designed for convenient installation and replacement, minimizing downtime during maintenance.

Compatibility with conveyor systems: Ensure the brushes are compatible with your conveyor systems, adhering to any static grounding, silicone-free, or other specific criteria.

Why Choose Us:

At Shanghai Bursten, we are dedicated to providing cutting-edge conveyor strip brushes that meet the highest industry standards. Our team of experienced engineers and manufacturers work tirelessly to design and produce brushes that deliver exceptional performance, durability, and reliability.

With a commitment to innovation and customer satisfaction, we strive to understand your unique requirements and tailor our solutions accordingly. Our conveyor strip brushes are backed by superior quality control processes, ensuring consistent performance and dependability.

Summary:

Conveyor strip brushes are essential tools for maintaining clean and efficient conveyor systems, ensuring seamless operations and minimizing costly downtime. These specialized brushes offer unparalleled protection, versatility, and durability, contributing to increased productivity, extended equipment lifespan, improved safety, and significant cost savings.

At Shanghai Bursten, we take pride in offering a comprehensive range of high-quality conveyor strip brushes that are designed to meet the demanding requirements of modern industrial environments. Our commitment to excellence, innovation, and customer satisfaction sets us apart, making us the preferred choice for industries seeking reliable and effective conveyor protection solutions.

Call to Action:

Elevate your conveyor operations with our cutting-edge conveyor strip brushes and experience the benefits of superior protection, enhanced productivity, and long-lasting performance. Contact us today to discuss your specific requirements and let our experts recommend the ideal brush solution for your conveyor systems. Invest in the future of your operations and enjoy the peace of mind that comes with choosing the right partner for your conveyor protection needs.

Conveyor Track Brushes

Conveyor track closeout side brushes are designed to keep debris and dirt out of the track of the conveyor. Appropriate for both inside and outside applications, these brushes also prevent unwanted pests and birds from nesting in the track. These flexible brushes are long-lasting and work to keep you conveyor performing at its best.

Whether sealing overhead track conveyors like the design above to keep out nesting birds or ground floor conveyors where keeping the track clean is the issue, Flex-Guard has the flexibility to design the correct mounting bracket and brush to meet your criteria. Excluding dirt, debris, or small parts from the in ground or floor conveyor is the secret to keeping the conveyor working. We can design the bristle to meet drop criteria, static grounding and silicone free conditions. The more time spent defining the needs, the better the solution.

Paint Booth Conveyor Track Closeout Brushes

Washer Conveyor Belt Brushes

Conveyor Track Brush Seal Mounting Brackets

Shanghai Bursten Seals work well over any flat or irregular surfaces and are completely flexible. Flex-Guard Brush seals can be used in numerous applications. Many additional standard and special brush mounting designs are available to meet your specific needs. Brush mountings come in aluminum as standard material. Stainless Steel is also available. Mill finish is standard, other finishes are available; other designs are stock.

Click on your choice of Brush Mountings below to view detailed specifications:

Keywords

Conveyor strip brushes

Bursten people are dedicated to help customers solve tough finishing problem.

Contact us

Classification

Related products

There is no relevant data for the time being, please add it in the background!